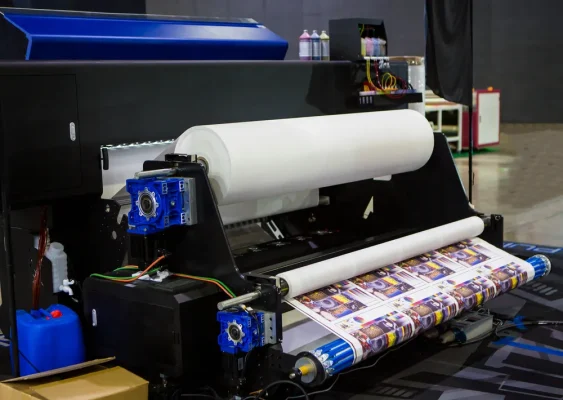

What is Sublimation Printing and how does it work?

Are you seeking a printing method capable of producing vibrant and durable prints? If so, Sublimation Printing may be the suitable choice for you, as it’s a popular and practical option for printing on materials such as fabric, plastic, metal, ceramic, as well as glass.

In this article, we’ll explore the basics of Sublimation Printing, including how it works and the advantages it offers compared to other printing methods. We’ll also discuss the materials that can be used with this printing method and address other common questions. By the end of the piece, you’ll have a clearer understanding of what Sublimation Printing is and why it’s an excellent choice if you’re running a Sublimation Printing workshop.

I. What is Sublimation Printing and how does it work?

Sublimation printing is a digital printing process that utilizes heat and pressure to transfer ink onto various materials.

Here is the complete sublimation printing process:

- Print your design onto special sublimation transfer paper using sublimation ink.

- Place the printed paper onto the product and use a heat press machine to apply heat.

- The heat converts the ink into vapor, which is then absorbed by the material.

- As a result, you obtain a vibrant, durable print that is fade-resistant and resistant to peeling over time.

II. The Pros and Cons

1. The Pros

Now that you understand how sublimation printing works, let’s delve into its advantages and disadvantages.

- Vibrant and sharp color results: One of the most intriguing aspects of sublimation printing is its ability to produce vivid and detailed prints. Thanks to the high temperature used in the process, the lines become crisp, and colors do not fade like traditional printing methods.

- Superior print durability: An important aspect to note about sublimation printing is that the ink is not just printed on the surface of the material. Instead, it is absorbed directly into the material, becoming an integral part of it. This is why sublimation prints do not fade, peel, or wash off easily, lasting much longer than prints from other printing methods.

- Quick turnaround time: Another advantage of sublimation printing is its fast turnaround time. Since the process is digital and does not require creating a physical screen or stencil, sublimation printers can quickly produce high-quality prints with less manual labor.

- Versatile application on various products, materials: When it comes to material choices, sublimation printing is flexible and offers ample room for creativity. You can create custom clothing, bags, mugs, mousepads, and much more.

- Environmentally friendly: A final benefit of sublimation printing is that it is a relatively eco-friendly printing process. Unlike traditional methods that use water-based and solvent-based inks, sublimation printing uses dry ink. The dry ink is absorbed into the material during printing, leading to minimal waste and reducing environmental impact. Additionally, it reduces the amount of wasted ink by only applying it to necessary areas.

2. The Cons

Sublimation printing also comes with its share of limitations. Here are 5 key drawbacks to consider before choosing this printing method:

- Material limitations: It’s important to note that sublimation printing only works on 100% polyester fabric or fabric blends with a high polyester content. The less polyester in your fabric, the more likely the print will fade. This is because the chemical properties of sublimation ink require synthetic fibers to adhere to and produce good print results. If you’re interested in sublimation printing on cotton, silk, or leather, it won’t be the right choice. Sublimation ink will struggle to adhere to natural fibers or will quickly wash away.

- Limited color options: Sublimation printing typically is only available for products with white or very light colors. Since there is no white ink in sublimation printing, and sublimation inks cannot brighten the background color, printing on dark-colored products may not yield the expected results. For example, printing a bright magenta color on a black shirt will result in a black print with a faint red tint.

- Potential for white spots: When sublimation printing on finished products, there may be areas that are not printed correctly, leaving behind white spots. This often occurs around seams or due to misfolding during the printing process.

- Equipment costs: The machinery and equipment required for sublimation printing can be relatively expensive, especially for small businesses or individuals looking to start.

- Chemical reactivity: Sublimation inks may react with certain chemicals in the materials being printed, leading to color changes or printing performance issues.

III. Comparison with other textile printing processes

| Sublimation Printing | Flexo printing | Screen printing | Print Flock | |

| No restrictions on designs | V | X | X | X |

| Sharpness | V | V | V | V |

| Material properties do not change | V | X | X | X |

| Cotton can be printed | X | V | V | V |

| Good durability | V | X | V | V |

| Good cost | V | X | X | V |

| Price performance ratio during use | V | X | X | V |

IV. Conclusion

Sublimation printing is increasingly becoming the leading technology in the textile industry with numerous versatile applications. Currently, Teroprints provides a wide range of services related to this technology.

You can explore more about Hawaiian Islands, Hawaiian Shirts and Swim Trunks to discover their unique styles, history, and tips for choosing the right one for you. For a wide range of stylish options, visit Teroprints Shop, where you’ll find a collection of Swim Trunks and Hawaiian Shirts that are perfect for any occasion.

Don’t forget to stay connected with Teroprints on Instagram, Pinterest, and Facebook to keep up with our latest product releases and updates. Follow us for the newest trends and exclusive deals!

You can refer to the articles below for more helpful information:

- The most stylish ways to coordinate outfits with T-shirts

- 5 Quick, simple, space saving methods to fold Polo Shirts

- How to wash polyester: Tips for keeping your clothes durable and beautiful

- How to lace Converse shoes: 9 Unique and stylish ways to tie Converse shoe laces easily

FAQs - Sublimation Printing

Sublimation printing is a digital printing technique where heat and pressure are used to transfer ink onto various materials, creating vibrant and durable prints.

Sublimation printing works best on materials with a high polyester content or polyester-coated surfaces. These include polyester fabrics, ceramic tiles, metal sheets, and certain plastics.

Sublimation printing offers advantages such as vibrant colors, durability, and eco-friendliness. Unlike traditional methods, sublimation ink is absorbed into the material, resulting in prints that are fade-resistant and washable. However, it has limitations, such as the requirement for specific materials and the potential for color variations on darker substrates.